TIG 315P AC/DC

The TIG 315P AC/DC is a professional-grade industrial TIG/MMA welding machine designed for precise and controlled welding on a wide range of metals — including aluminum, stainless steel, and mild steel. Powered by a 3-phase input and packed with advanced features like adjustable pulse frequency, slope control, peak/background current settings, and start/crater current, it delivers exceptional control over arc characteristics. Built with a tri-proof air duct design for durability and heat management, this unit is ideal for high-duty fabrication environments.

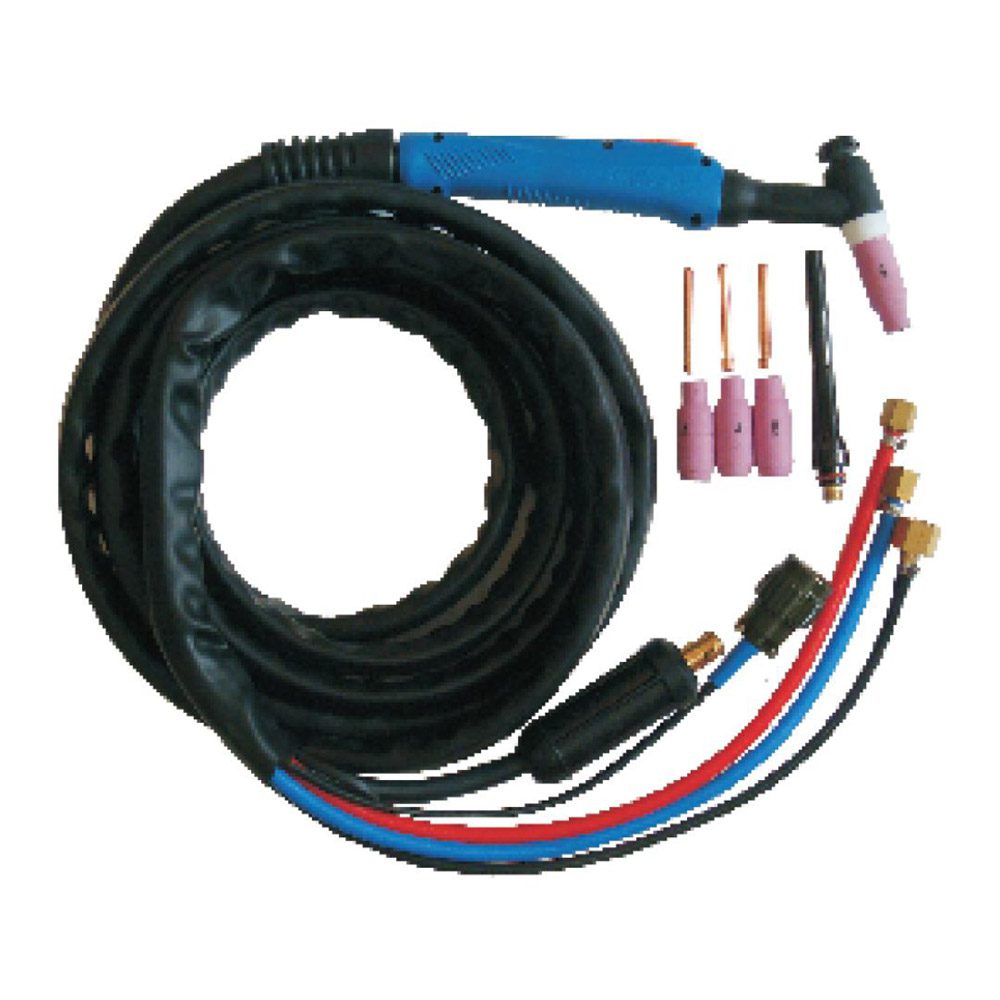

Available in Pack: Single-unit pack with inverter power source, water-cooled TIG torch, and earth clamp with cable and Europlug.

Key Features

- HF TIG and MMA dual process

- Pulse frequency and width adjustable

- Peak, background, start, and crater current controls

- Up-slope and down-slope adjustable for soft arc transitions

- Post-flow control for weld pool protection

- Digital display with simplified rotary knob interface

- Tri-proof air duct for better heat dissipation and dust resistance

- 3-phase 415V input for stable industrial performance

- Built-in protection against under-voltage, over-voltage, and over-current

Industries

- Pressure Vessel Manufacturing

- Aluminum & Stainless Steel Fabrication

- Pipe Installation

- Structural Steel Welding

- Industrial Equipment Maintenance

Processes

- TIG (High-Frequency Start)

- MMA (Manual Metal Arc)

Additional Details

- For critical weld applications, use crater current control to avoid crater cracking.

- Slope settings help transition smoothly between arc starts and stops.

- Ensure clean shielding gas supply for optimal TIG arc stability.

- Store in a cool, dry place.

- Refer TDS for more information.

Product Details

| Parameter | TIG 315P AC/DC |

| Input Voltage | 3P – 415V ±15% |

| Frequency (Hz) | 50/60 |

| Rated Input Current (A) | 17.2 (TIG), 17.0 (MMA) |

| Rated Input Power (kVA) | 12.36 (TIG), 12.22 (MMA) |

| Output Current Range (A) | 12–300 (TIG), 12–245 (MMA) |

| Output Voltage Range (V) | 10.4–39 (TIG), 20.4–42 (MMA) |

| No-load Voltage (V) | 62 |

| No-load Power Loss (W) | 100 |

| Power Factor | 0.9 |

| Insulation Grade | F |

| Efficiency | >85% |

| Housing Protection Grade | IP21 |

| Weight (kg) | 36 |

| Dimensions (mm) | 609 × 332 × 622 |

Raise a Quote

Related Products

-

The TIG 400 is a robust, industrial-grade TIG/MMA welding machine designed for high-duty operations in structural fabrication, pipeline welding, and pressure vessel applications. Equipped with advanced IGBT inverter technology, this machine delivers seamless arc starts using high-frequency ignition and provides complete control through adjustable arc force, up/down slope, and post-flow functions. Built for demanding environments, the TIG 400 combines performance with safety, passing the 3750V AC dielectric test and featuring intuitive controls for professional results. Available in Pack: Single-unit pack with inverter power source, water-cooled TIG torch, and earth clamp with cable and Europlug.

-

The TIG 250 is a compact yet high-performance TIG/MMA welding machine, designed for precision welding in structural and piping applications. Powered by 100 kHz MOSFET inverter technology and equipped with four heat sinks for optimal thermal dissipation, it delivers smooth arc control with dual TIG (HF) and MMA capabilities. Features include a digital current display, post-flow control for seam protection, and automatic arc force/hot start in MMA mode. Lightweight yet rugged, the TIG 250 is ideal for maintenance, light fabrication, and pipe welding. Available in Pack: Single-unit pack with inverter power source, TIG 26 torch, and earth clamp with cable and Europlug.

-

The MIG 400 is a professional-grade dual-process welding machine designed for high-capacity industrial use. With an output of up to 400A, it supports both MIG and MMA welding processes and features advanced IGBT inverter technology for superior arc stability. It includes adjustable inductance, 2T/4T operation, and a separate external wire feeder with voltage and current control. Equipped with digital meters, overload protection, and a dust-free cooling system, the MIG 400 is engineered to handle demanding fabrication and equipment manufacturing tasks with reliability and ease. Available in Pack: Single-unit pack with inverter power source, 3 m MIG torch and cable assembly, 3 m earthing cable and clamp, wire feeder, and accessories.