Welcome To StarBlaze

Powering Industries with Solutions That Last

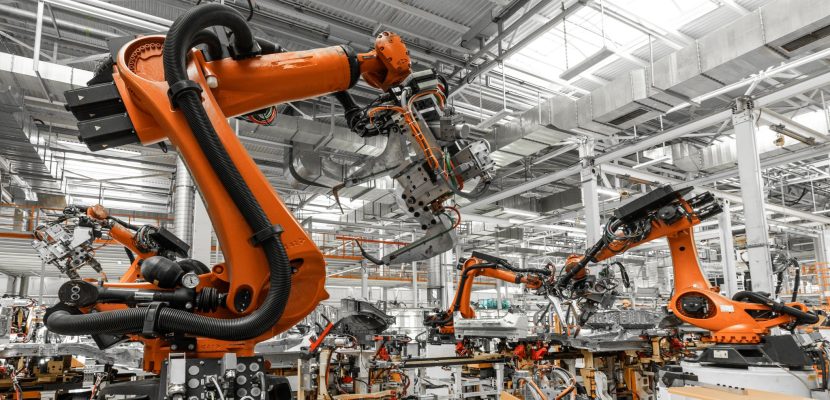

With 20+ years of experience, StarBlaze, a brand of Stellaris Specialities India Limited, has been at the forefront of India’s industrial manufacturing sector, not just as suppliers, but as long-term partners in growth. With in-house R&D, four ISO-certified manufacturing facilities, and a pan-India distribution network, we’ve built a reputation for delivering high-performance solutions across welding, automation, maintenance and industrial chemicals.

What sets us apart isn’t just the scale of what we do, but how we do it. Every solution we offer is the result of deep technical expertise, a problem-solving mindset, and a genuine commitment to our clients’ success, embodied by our 1,200+ employees. Whether it’s improving weld integrity, streamlining assembly with robotics, or protecting critical infrastructure, StarBlaze stands for reliability, innovation, and service that puts you first.

We engineer the tools that shape the future of manufacturing.

Why Choose StarBlaze

Our Products & Services

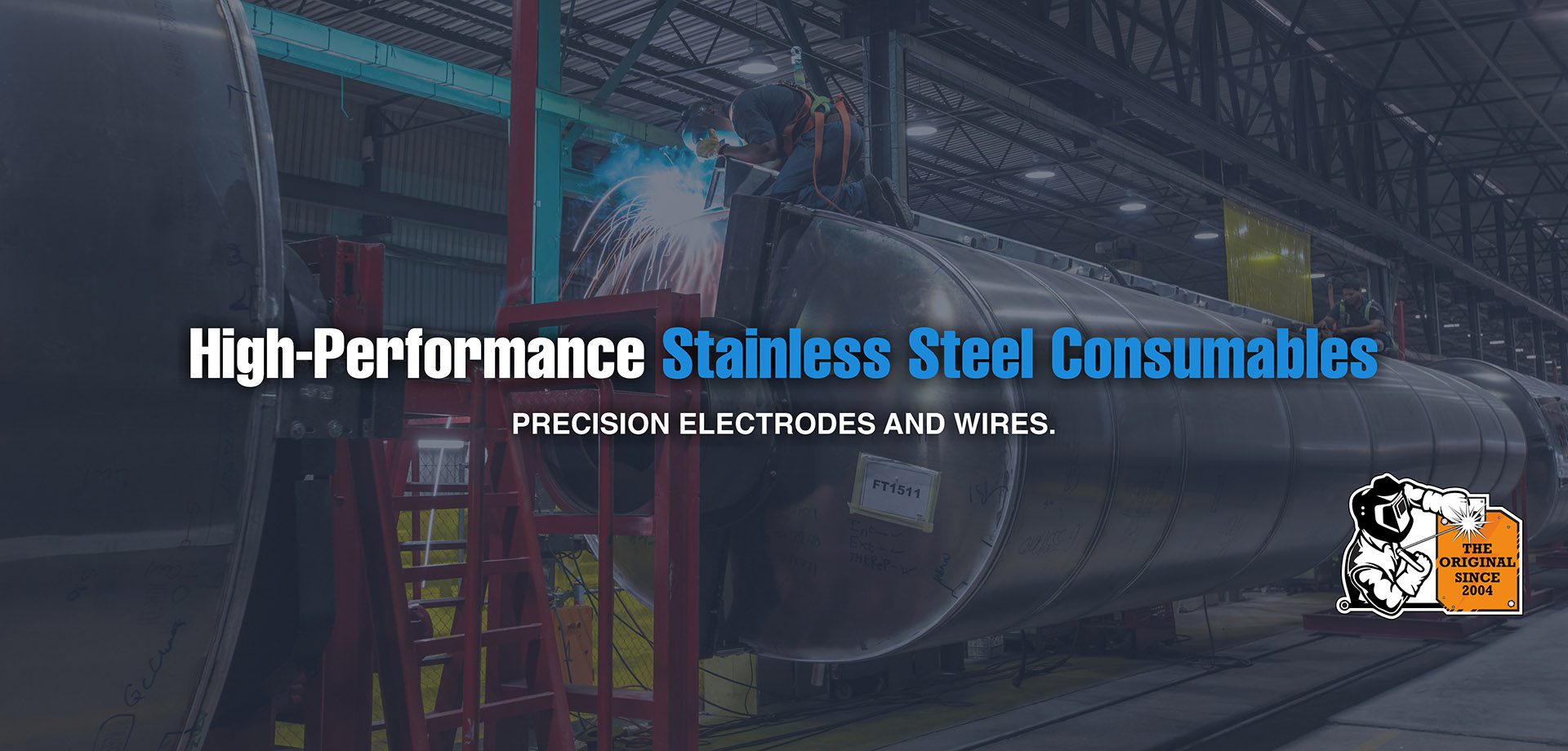

High-performance electrodes for mild steel, stainless, hard-facing, low alloy, and nickel alloy welding applications.

Flux-cored, stainless, and copper-free wires designed for smooth feeding, consistent arcs, and durable weld strength.

ARC, MIG, TIG, SAW, and Plasma machines built for industrial reliability, arc stability, and long-duty cycles.

Specially alloyed for reliable repair, reclamation, and build-up in demanding industrial maintenance

applications.

Protective sprays and coatings for lubrication, corrosion resistance, and improved surface life in tough environments.

Primers and speciality paints formulated for high heat, chemical resistance, corrosion protection, and insulation.

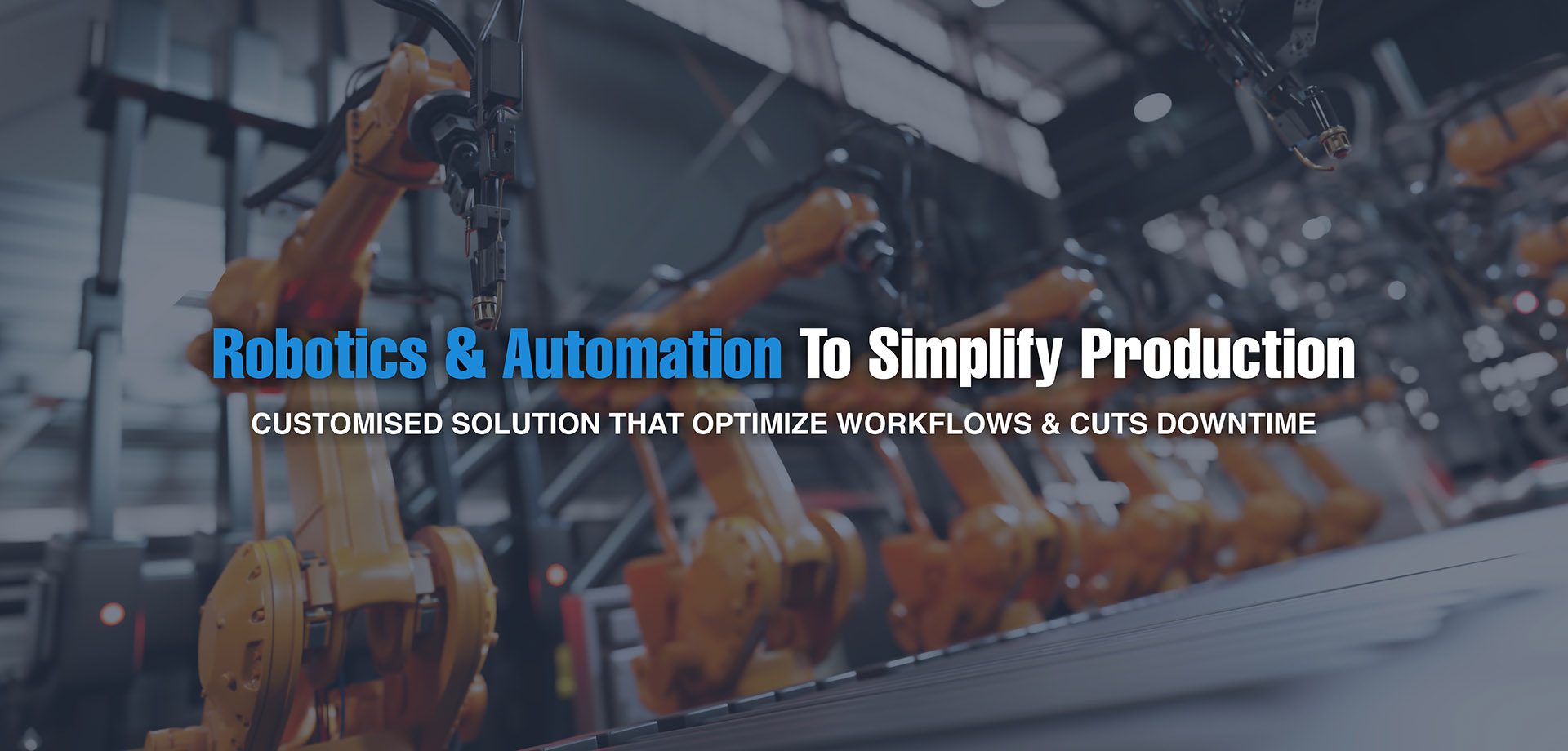

End-to-end automation solutions for welding, handling, palletising, and process optimisation across industrial setups.

Hands-on programs designed to upskill welders and industrial technicians for modern factory needs.

Our Solutions

Industries We Serve

Client Speak

StarBlaze Knowledge Hub

Welding: The Unsung Backbone of India’s Industrial Growth

Revolutionizing Welding: StarBlaze’s Complete Automation Solutions for the Future of Fabrication

Reducing Industrial Downtime with Smarter Maintenance: How StarBlaze MRO Products Keep You Running

Industrial Protection That Lasts: How StarBlaze Protective Coatings Help You Fight Corrosion and Time