StarBlaze 32F02 Thermal Energy Saver Coating

StarBlaze 32F02 is a composite ceramic-based, single-component thermal insulating coating designed to reduce heat loss and protect steel surfaces in high-temperature environments. With a temperature resistance of up to 600 °C and low thermal conductivity, it cuts radiant heat transfer, preventing energy loss and improving worker safety.

Its ceramic matrix forms a barrier that reflects UV radiation and resists moisture, mold, and mildew, while also protecting substrates from oxidation and corrosion. StarBlaze 32F02 is ideal for kilns, chimneys, boilers, and industrial exhaust systems where reliable thermal insulation is critical.

Available Packs: 20L

Key Features

- Reduces heat loss via radiation and conduction

- Excellent thermal insulation with low emissivity

- High-temperature resistance up to 600 °C

- Resists moisture, mold, and mildew infiltration

- Improves energy efficiency and saves heating costs

- UV protection over coated surfaces

- Self-priming formulation simplifies application

Industries

- Cement Plant Kiln and Preheater Shells

- Boilers (Inner and Outer)

- Heat Exchangers and Furnaces

- Metal Chimneys and Exhaust Manifolds

- Metal Roofing in Industrial Facilities

Processes

- High-Temperature Energy-Saving Coating Application

- Thermal Barrier Installation on Industrial Equipment

- Corrosion and Heat Loss Reduction on Metal Structures

- UV and Weather-Resistant Protective Layering

Tab Title

- Store in cool, dry place

- Refer TDS for more information

Raise a Quote

The information could not be saved. Please try again.

Thank You! Our team will connect with you shortly.

Related Products

-

StarBlaze 41A01 is a high-strength, steel-filled epoxy putty designed for structural repairs on metal components exposed to wear, corrosion, or mechanical damage. It is formulated for applications where high compressive and tensile strength, combined with temperature resistance up to 120°C, are critical. The putty cures to a dark grey, machinable finish with low shrinkage and superior bond strength. With an 8:1 mix ratio and 60-minute pot life, StarBlaze 41A01 provides ample working time for reshaping, rebuilding, or reinforcing metal surfaces. Once fully cured, it can be drilled, tapped, filed, or ground, making it ideal for restoring precision parts, worn shafts, corroded tank sections, and other metallic equipment. Built for harsh industrial settings, it ensures long-term performance where welding or component replacement is impractical. Available Packs: 1 Kg Kit

-

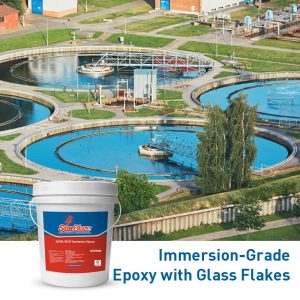

StarBlaze 32F09 VEGF is a high-build, two-part epoxy coating enhanced with glass flakes to deliver outstanding performance against corrosion, erosion, and aggressive chemicals. Suitable for continuous immersion, it offers thermal resistance up to 150 °C when submerged and up to 280 °C in non-immersed service. This solvent-free system forms a dense, impermeable barrier over prepared metal surfaces. Its excellent abrasion resistance (<50 mg/1000 cycles) and strong adhesion (pull-off >1500 psi) make it ideal for tank interiors, ducting, exhaust manifolds, and other process equipment subjected to extreme temperatures and chemicals. The product also provides dielectric properties up to 16 kV BDV, adding safety in electrostatic applications. Available Packs: 5 Kg, 20 Kg Sets

-

StarBlaze 33B01 is a high-strength, epoxy-based, self-levelling screed formulated to deliver superior load-bearing capacity and chemical resistance on concrete substrates. Blended as a three-component system, it cures to a dense, abrasion-resistant layer ideal for use under epoxy top coats or as a standalone heavy-duty flooring solution. Designed for high-impact and chemically aggressive environments, 33B01 achieves compressive strengths over 36 MPa, tensile strengths exceeding 10 MPa, and bond strength surpassing the cohesive strength of the concrete itself. Its self-levelling properties ensure uniform surfaces even over uneven or repaired substrates. Suitable for acid bunds, containment zones, production floors, and vehicle traffic areas, it provides reliable performance where hygiene, durability, and resistance to industrial chemicals are essential. Available Packs: Three pre-weighed packs (Base, Hardener, Aggregate)