StarBlaze Prime CI 99

AWS A5.15: ENi-CI | EN ISO 1071: EC Ni-CI 1

97.5% Nickel Core | Low Amperage Welding | Grey Cast Iron Specialist

StarBlaze Prime CI 99 is a graphite-coated, pure nickel core wire electrode engineered for high-integrity welding of grey cast iron, malleable iron, and cast iron components under fatigue. Delivering soft machinability and a stable, low-spatter arc even at low current, this electrode ensures minimal dilution and excellent results on aged, cracked, or misaligned castings. Ideal for rectification work and critical repairs across casting industries.

Available Packs

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm, 4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- 97.5% pure nickel deposit for high ductility and low residual stress

- Low heat input and excellent arc control

- Soft, easily machinable weld metal and fusion zone

- Smooth arc with low spatter and easy slag removal

- Best suited for rectification, fatigued cast parts, and aged repairs

- Casting rectification and quality correction

- Engine block and cylinder head repairs

- Tool machines, housings, and valve bodies

- Foundry maintenance and precision refurbishment

- Shielded Metal Arc Welding (SMAW / MMA)

- DC+ polarity recommended

- All-position usability

- Ideal for low amperage repairs with tight dimensional control

- Suitable for repairs requiring soft machinability post-welding

- Keep dry; redry at 200–250°C for 1 hour before use

- Clean weld zone thoroughly (remove cast skin and oxide)

- Apply short weld beads; width ≤ 2× diameter, length ≤ 10× diameter

- Hammer welds immediately post-deposition to relieve stress

Product Details

Typical Weld Metal Chemical Composition (%)

| C | Si | Mn | Ni | Fe |

| 1.00 | 0.50 | 0.35 | 97.50 | Rem. |

Typical Mechanical Properties (All Weld Metal)

| Tensile Strength

Rm (N/mm2) |

Hardness HB |

| 450 | 165 approx. |

Recommended Welding Parameters

| Diameter (mm) | Amperage Range (A) |

| 2.50 | 50-70 |

| 3.15 | 70-90 |

| 4.00 | 100-130 |

Raise a Quote

Related Products

-

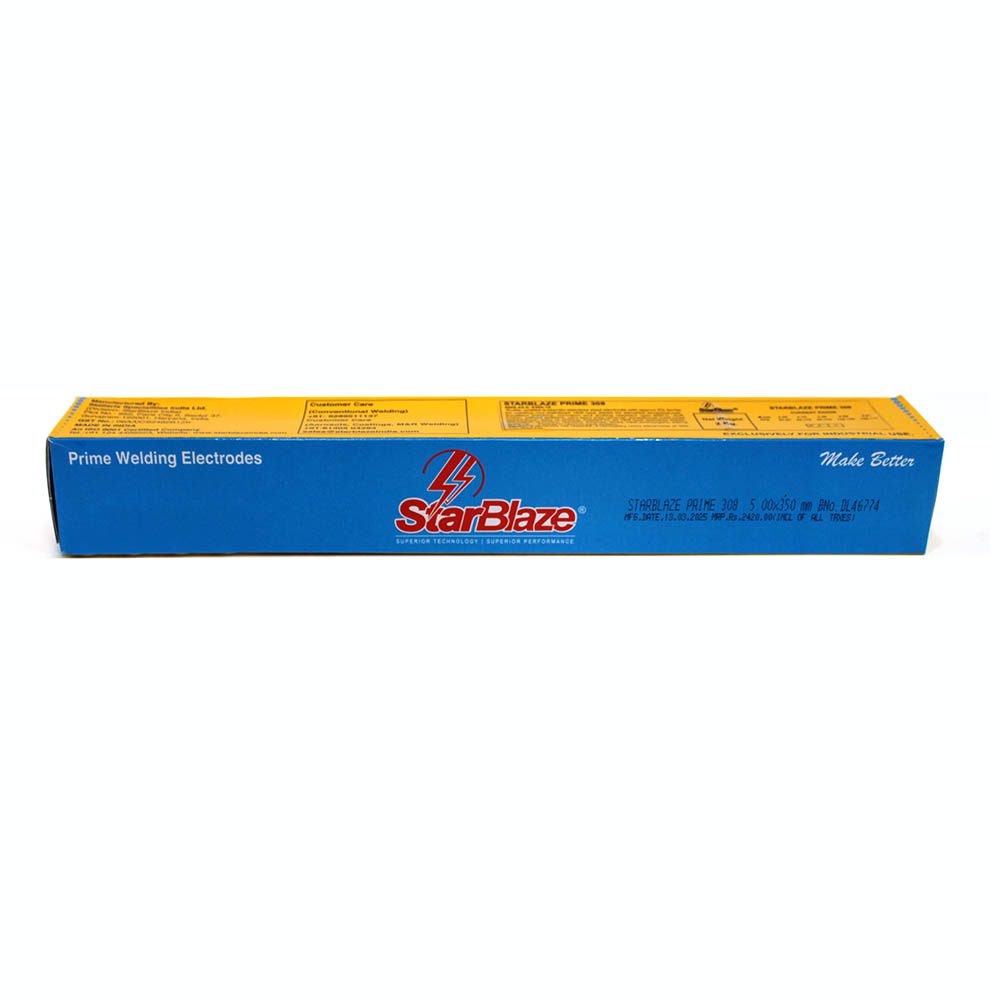

AWS A5.4: E308L-17 | DIN EN ISO 3581-A: E 19 9 LR 32 | DIN EN 1600: E 19 9 LR 32 | Werkstoff Nr: 1.4316 Low Carbon Core, Corrosion-Resistant, Smooth Bead Appearance Low carbon rutile-silica coated stainless electrode with 6–8% ferrite for welding 18/8-type austenitic steels. Delivers soft fusion with low moisture absorption and minimal spatter. Offers excellent slag detachability and smooth weld finish—ideal for service conditions from –120°C to +350°C in tanks, pipes, and heat exchangers.

- Available Packs

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm, 4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- Available Packs

-

AWS A5.1: E 6010 | EN 499: E 38 3 C 21 | DIN EN ISO 2560-A: E 38 3 C 21 Deep Penetration, Fast Freezing, Radiographic Quality Welds High cellulose-coated deep penetration electrode for radiographic-quality welds. Suitable for all-position welding of pipes and pipelines using stove pipe and conventional techniques. Delivers strong arc force, rapid freeze characteristics, and excellent mechanical properties. Available Packs

-

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm ,4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

-

-

AWS A5.4: E308L-16 | DIN 8556: E19 9 LR 23 | DIN EN 1600: E19 9 L R 32

Low Carbon. Crack-Resistant. Versatile.

A rutile-basic coated stainless steel electrode, E308L-16 is designed for welding austenitic 18/8 Cr-Ni stainless steels. With a low carbon core wire (308LER) and optimized ferrite (~8%), it offers maximum crack resistance, smooth arc characteristics, and superior corrosion resistance. The electrode produces soft fusion with minimal spatter, excellent slag detachability, and aesthetically clean weld beads. Suitable for use at service temperatures from -120°C to +350°C.