TIG 400

The TIG 400 is a robust, industrial-grade TIG/MMA welding machine designed for high-duty operations in structural fabrication, pipeline welding, and pressure vessel applications. Equipped with advanced IGBT inverter technology, this machine delivers seamless arc starts using high-frequency ignition and provides complete control through adjustable arc force, up/down slope, and post-flow functions. Built for demanding environments, the TIG 400 combines performance with safety, passing the 3750V AC dielectric test and featuring intuitive controls for professional results.

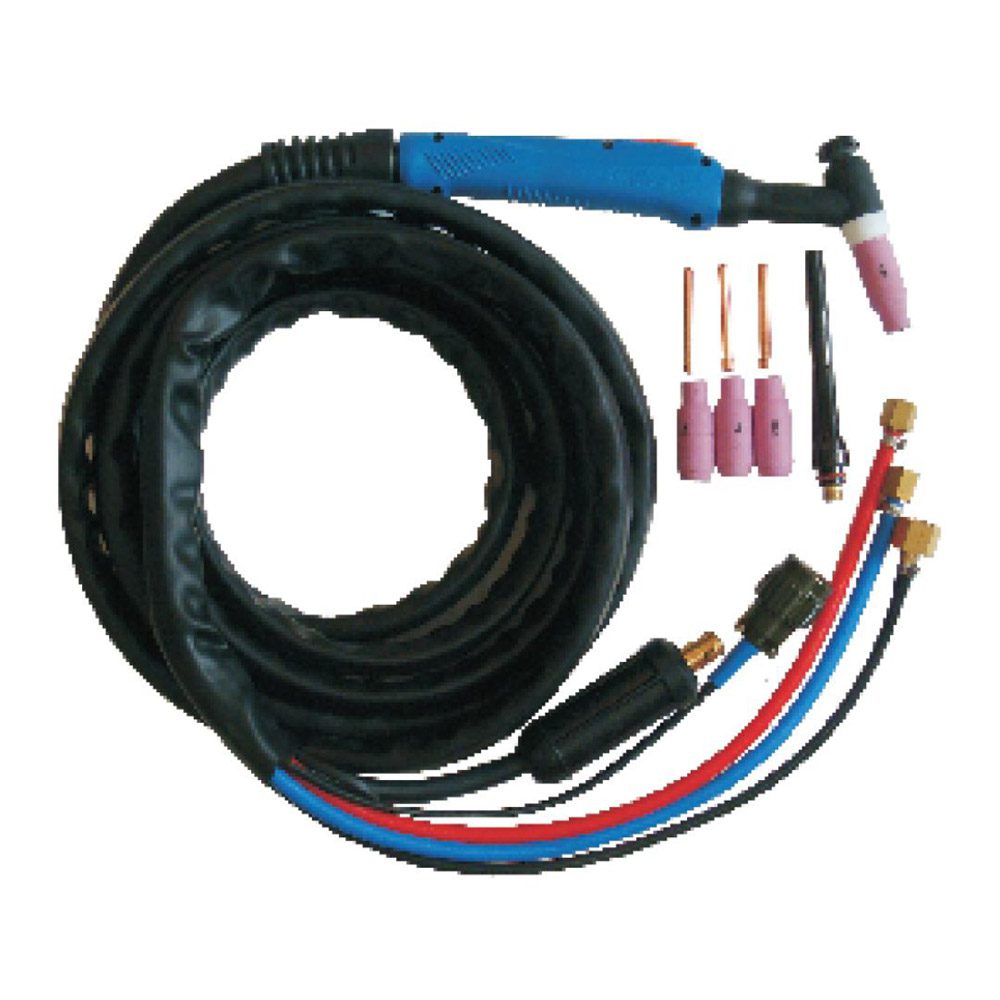

Available in Pack: Single-unit pack with inverter power source, water-cooled TIG torch, and earth clamp with cable and Europlug.

Key Features

- HF TIG and MMA dual welding process

- 400A output for industrial-scale applications

- High-frequency arc start for smooth ignition

- Adjustable up slope, down slope, and arc force

- 2T/4T operation modes for short and long weld cycles

- LED display for preset current selection

- Dielectric strength tested to 3750V AC for safety

- IGBT inverter for stable arc and high efficiency

- Built to handle mild steel, stainless steel, and alloyed materials

Industries

- Pipe Welding & Installation

- Pressure Vessel Fabrication

- Structural Steel Projects

- Heavy Equipment Maintenance

- Industrial Fabrication Units

Processes

- TIG (High-Frequency Start)

- MMA (Manual Metal Arc)

Additional Details

- For optimal weld starts, use HF ignition with proper tungsten prep.

- Use slope functions for cleaner weld finish, especially at start/end points.

- Designed for 3-phase operation in continuous welding scenarios.

- Store in a cool, dry place.

- Refer TDS for more information.

Product Details

| Parameter | TIG 400 |

| Input Voltage | 3P – 415V ±15% |

| Frequency (Hz) | 50/60 |

| Rated Input Current (A) | 20.0 (TIG), 24.3 (MMA) |

| Rated Input Power (kVA) | 14.38 (TIG), 17.50 (MMA) |

| Output Current Range (A) | 10–400 (TIG & MMA) |

| Output Voltage Range (V) | 10.4–26 (TIG), 20.4–36 (MMA) |

| No-load Voltage (V) | 65 |

| No-load Power Loss (W) | 100 |

| Power Factor | 0.9 |

| Insulation Grade | F |

| Efficiency | >85% |

| Housing Protection Grade | IP21 |

| Weight (kg) | 25 |

| Dimensions (mm) | 508 × 244 × 423 |

Raise a Quote

Related Products

-

Product Description The MIG 500HD is a robust, high-performance MIG/MMA welding machine designed for heavy-duty industrial applications. It offers up to 500A output and advanced arc control with adjustable inductance, crater current, and crater voltage features. Engineered with IGBT inverter technology, this machine ensures stable, efficient welding across a range of wire diameters (solid and flux core) and material types. Its external wire feeder, intelligent parameter presets, and dual digital meters make it ideal for long, high-intensity welding operations in fabrication and manufacturing settings. Available in Pack: Single-unit pack with inverter power source, 3 m welding torch and cable assembly, 3 m earthing cable and clamp, and wire feeder with accessories.

-

The MIG 500 is Starblaze’s most advanced and powerful dual-process welding machine, delivering up to 450A output for intensive industrial applications. Built with advanced IGBT inverter technology, this 3-phase MIG/MMA unit includes a fully featured external wire feeder, adjustable inductance, 2T/4T operation, crater control, and intelligent parameter presets based on wire size and type. Its digital meters, robust cooling system, and corner-protected chassis make it a reliable performer in high-load environments like equipment manufacturing and structural fabrication. Available in Pack: Single-unit pack with inverter power source, 3 m welding torch and cable assembly, 3 m earthing cable and clamp, and wire feeder with accessories.

-

The ARC 270D is a high-performance MMA welding machine designed for versatile, dual-voltage operation (220V/415V ±15%). With enhanced output power and compatibility for electrodes ranging from 2.5 mm to 4.0 mm, this machine combines RILAND’s RICHIP chip, robust IGBT technology, and intelligent MCU control to deliver consistent performance across heavy-duty fabrication and repair applications. It features a dual-knob control panel for welding current and arc force, a VRD switch, and an LED display — offering professional-grade features in a compact 5.5 kg unit. Available in Pack: Single-unit pack with inverter power source, 2 quick plugs, and 1 allen key.