StarBlaze Prime 10018-G

AWS A5.5: E10018-G H4

High Impact Strength | Low Hydrogen | Smooth Bead Finish

A basic coated low hydrogen LMA (low moisture absorption) iron powder electrode, designed for welding of high strength steels under dynamic loading conditions. Features exceptional arc stability, low spatter, excellent slag detachability, and a finely rippled weld bead. Suitable for structural welding in earthmoving, offshore, and heavy equipment applications.

Available Packs

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm, 3.20 mm x 450 mm, 4.00 mm x 450 mm, 5.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- Excellent weldability in all positions

- High yield strength (≥ 680 N/mm²) and tensile strength (up to 850 N/mm²)

- Impact energy ≥ 47 J at -60°C

- Smooth, stable arc with excellent slag removal

- X-ray quality welds with very low hydrogen content

- High strength structural fabrication

- Earthmoving & mining equipment

- Dynamic loading and mechanical restraint joints

- Offshore structures and critical assemblies

- Shielded Metal Arc Welding (SMAW / MMA)

- DC+ polarity

- All-position welding: PA, PB, PC, PF, PE, PF2

- Compatible base materials: S620–S690, P690, L415–L555, BH65

- Charpy impact: 47 J minimum at -60°C

- Diffusible hydrogen: < 3 ml / 100g weld metal

- Re-drying: 300–350°C for 1–2 hours; max 3 cycles

- Ensure dry storage and moisture protection prior to use

Product Details

Typical Weld Metal Chemical Composition (%)

| C | Mn | Si | P | S | Ni | Mo |

| 0.06 | 1.40 | 0.50 | 0.020 | 0.015 | 2.50 | 0.40 |

Typical Mechanical Properties (All Weld Metal)

| Yield Strength

Rp (N/mm2) |

Tensile Strength

Rm (N/mm2) |

Elongation

A5 (%) |

Charpy Impact Energy

ISO-V(J) -60°C |

Diffusible Hydrogen

(per 100g weld metal) |

| ≥ 680 | 760-850 | ≥ 18 | ≥ 47 | < 3ml |

Recommended Welding Parameters

| Diameter (mm) | Amperage Range (A) |

| 2.50 | 65-95 |

| 3.15 | 90-140 |

| 4.00 | 140-185 |

| 5.00 | 180-240 |

Raise a Quote

Related Products

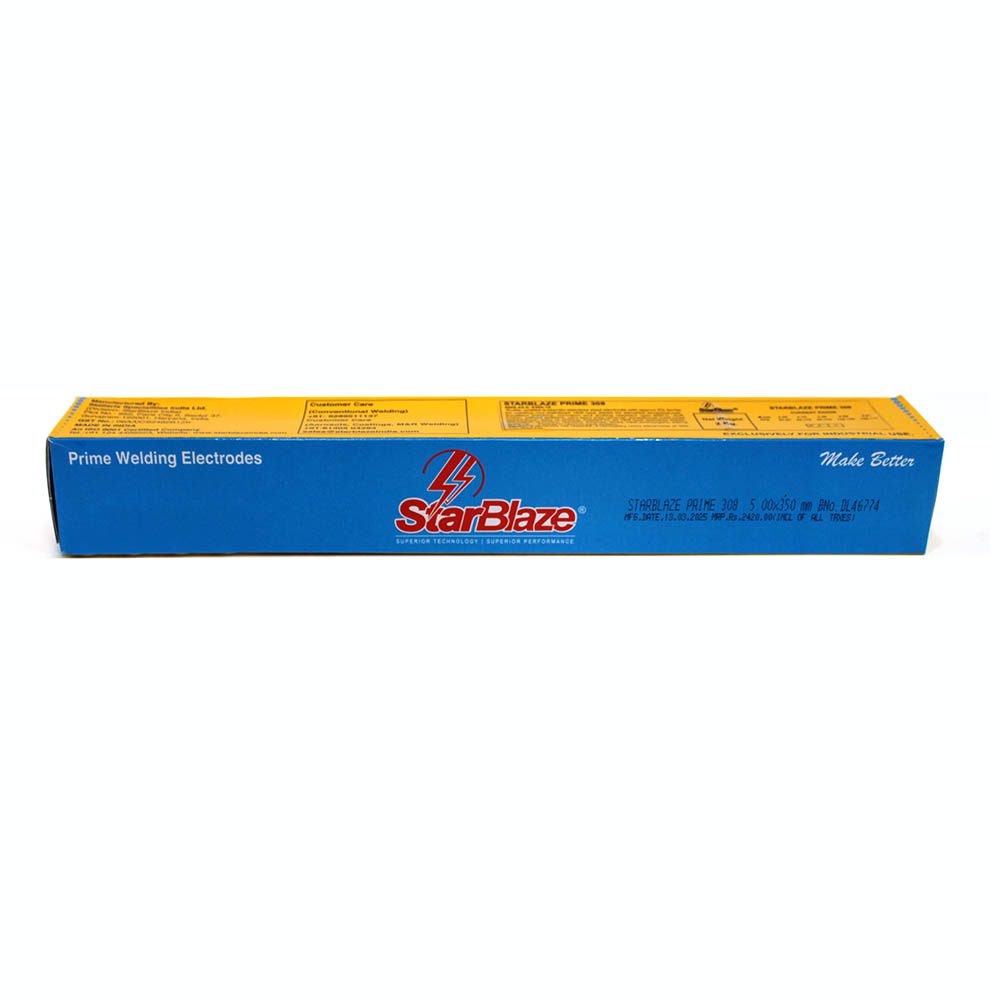

-

AWS A5.4: E308-16 | DIN EN ISO 3581-A: E 19 9 R 12 | DIN EN 1600: E 19 9 R 12 | Werkstoff Nr: 1.4316 P Crack-Resistant, Low Spatter, High-Temperature Stability Rutile-coated stainless steel electrode with ~5% ferrite content for welding non-stabilised 18/8 austenitic steels. Offers excellent resistance to cracking, corrosion, and scaling up to 800°C. Produces spatter-free fusion, smooth bead appearance, and easy slag removal - ideal for boilers, piping systems, and reactors. Available Packs

-

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm ,4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

-

-

AWS A5.4: E307-26 | DIN EN ISO 3581-A: E 18 9 Mn Mo R 53 | Werkstoff Nr: 1.4370 Low Spatter, High Strength, Buffer-Layer Capable Stainless Electrode Rutile heavy-coated 19/9 Mn stainless steel electrode for joining and overlaying manganese steels, carbon steels, and high-sulphur/high-phosphorus alloys. Offers stable arc, low spatter, and excellent slag removal. Suitable for buffer layers and joining dissimilar metals in demanding structural applications. Available Packs

-

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm ,4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

-

-

AWS A5.4: E308L-16 | DIN 8556: E19 9 LR 23 | DIN EN 1600: E19 9 L R 32

Low Carbon. Crack-Resistant. Versatile.

A rutile-basic coated stainless steel electrode, E308L-16 is designed for welding austenitic 18/8 Cr-Ni stainless steels. With a low carbon core wire (308LER) and optimized ferrite (~8%), it offers maximum crack resistance, smooth arc characteristics, and superior corrosion resistance. The electrode produces soft fusion with minimal spatter, excellent slag detachability, and aesthetically clean weld beads. Suitable for use at service temperatures from -120°C to +350°C.