StarBlaze Prime 8018G

AWS A5.5: E8018-G H4 | DIN EN ISO 2560-A: E 50 5 B 35 H5 | EN 499: E 50 5 B 35 H5

115% Recovery | Moisture-Resistant Low Hydrogen | Tough for High-C-P-S Steels

A high-recovery, basic-coated low hydrogen electrode engineered for structural and fine-grained steels with higher carbon, phosphorus, or sulfur. Featuring excellent impact strength at –50 °C and radiographic-grade weld quality, it is a robust choice for cast steels, cement kilns, boiler tubes, and chassis applications. Maintains stable arc and smooth formability in moisture-exposed environments. Versatile performance across varied steel chemistries with dependable toughness and fill.

Available Packs

Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm,4.00 mm x 450 mm, 5.00 mm x 450 mm

Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

-

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- Superior notch toughness (≥ 60 J @ –50 °C)

- Stable arc, smooth bead flow, and excellent formability

- Low hydrogen moisture-resistant formulation (< 3 ml/100 g)

- Performs well on steels with higher C, P, and S contents

- High elongation and strength for pressurised applications

- 115% weld metal recovery—ideal for fabrication & buildup

- Boiler & Pressure Vessel Manufacturing

- Cement Kilns & Tube Sections

- Heavy Machinery & Earthmoving Equipment

- Machine Frames & Structural Chassis

- Pipework in Power & Refinery Systems

- Manual Metal Arc Welding (MMA / SMAW)

- AC and DC+ polarity compatible

- Positional use: PA, PB, PC, PF

- Excellent for multi-pass structural welding

- Suitable for various steel standards: EN 10025, EN 10216-1, EN 10113-2/3, EN 10213-2

- Re-dry at 300–350 °C for 2 hours before use

- Store dry to preserve hydrogen control performance

- Recommended for steels with medium to high mechanical restraint

Product Details

Typical Weld Metal Chemical Composition (%)

| C | Si | Mn | Ni | P | S |

| 0.07 | 0.40 | 1.50 | 0.60 | 0.022 | 0.015 |

Typical Mechanical Properties (All Weld Metal)

| Yield Strength

Rp (N/mm2) |

Tensile Strength

Rm (N/mm2) |

Elongation

A5 (%) |

Charpy Impact Energy

ISO-V(J) -50°C |

Diffusible Hydrogen

(Per 100g weld metal) |

| ≥ 500 | 560-680 | 28 | ≥ 60 | < 3 ml |

Recommended Welding Parameters

| Diameter (mm) | Amperage Range (A) |

| 2.50 | 60-90 |

| 3.15 | 100-140 |

| 4.00 | 140-180 |

| 5.00 | 180-230 |

Raise a Quote

Related Products

-

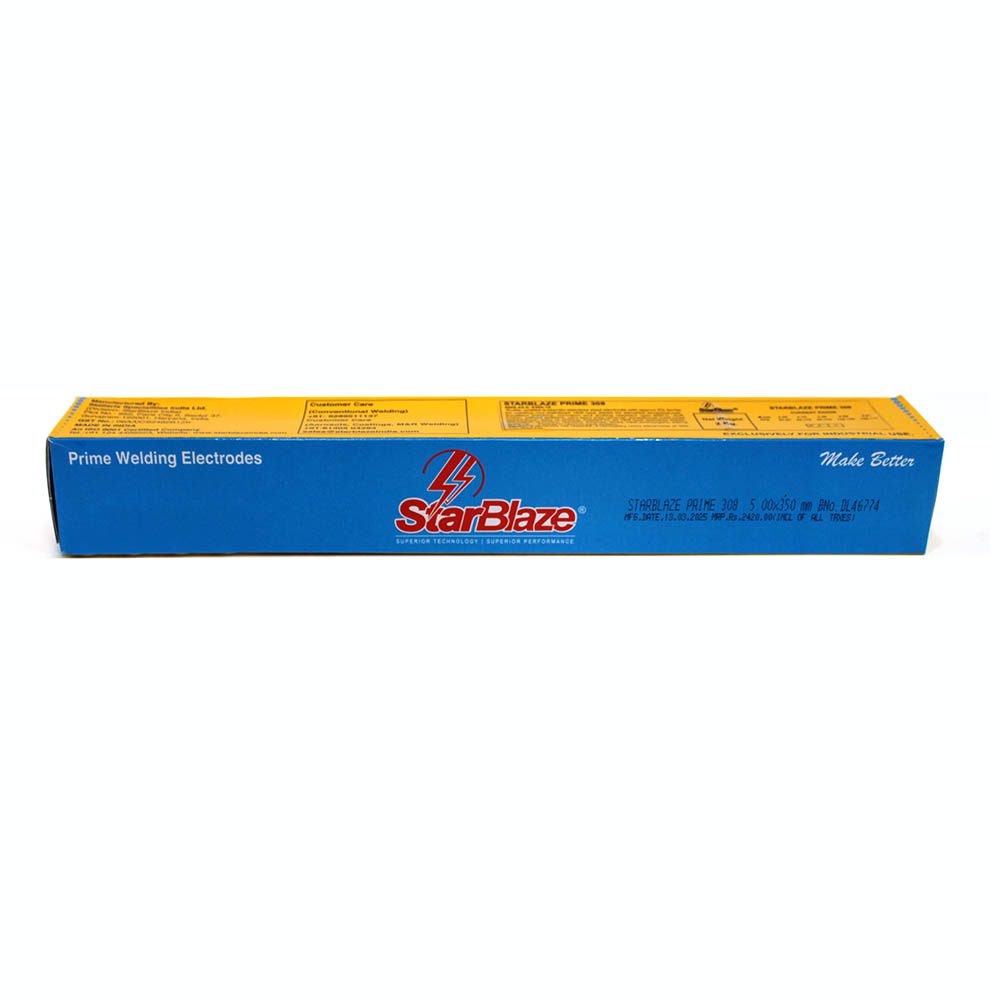

AWS A5.4: E308L-15 | DIN EN ISO 3581-A: E 19 9 LB 22 | DIN EN 1600: E 19 9 LB 22 | Werkstoff Nr: 1.4316 Cryogenic-Grade Strength, IGC-Compliant, Low Hydrogen Weldability Basic-coated stainless electrode with low hydrogen content for welding 304L and other austenitic stainless grades, offering excellent mechanical performance down to –196°C. Meets IGC Practice E and ASME Section II Part C standards. Designed for precise positional welding with smooth slag detachment and low spatter.

- Available Packs

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm,4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- Available Packs

-

AWS A5.1: E 7018-1 H4 | DIN EN ISO 2560-A: E 42 5 B 32 H5 | IS 814: EB 5629H3JX High Impact Notch Toughness/Crack Resistant, Ultra Smooth Bead, Superior Reliability A basic heavy-coated electrode for crack-free joint welding applications, producing tough bonds including on steels with 0.40% carbon content. Great metal recovery of up to 115% and optimal operating characteristics in varied positions while welding.

- Available Packs

- Dimensions: 2.40 mm x 350 mm, 2.50 mm x 350 mm, 3.15 mm x 450 mm, 3.20 mm x 450 mm, 4.00 mm x 450 mm, 5.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- Available Packs

-

AWS A5.4: E308L-16 | DIN 8556: E19 9 LR 23 | DIN EN 1600: E19 9 L R 32

Low Carbon. Crack-Resistant. Versatile.

A rutile-basic coated stainless steel electrode, E308L-16 is designed for welding austenitic 18/8 Cr-Ni stainless steels. With a low carbon core wire (308LER) and optimized ferrite (~8%), it offers maximum crack resistance, smooth arc characteristics, and superior corrosion resistance. The electrode produces soft fusion with minimal spatter, excellent slag detachability, and aesthetically clean weld beads. Suitable for use at service temperatures from -120°C to +350°C.